Cellulose Ethers Cas No. List

Cellulose Ether Manufacturing Process

Cellulose ethers are a group of important industrial materials derived from cellulose, a natural polymer found in the cell walls of plants. They are widely used in various applications such as adhesives, coatings, construction materials, pharmaceuticals, and food products. The manufacturing process of cellulose ethers involves several steps, including cellulose extraction, chemical modification, and purification. In this article, we will discuss the detailed process of cellulose ether manufacturing.

The first step in the manufacturing process of cellulose ethers is the extraction of cellulose from a natural source. The most common source of cellulose is wood pulp, which is obtained from trees through a process called pulping. Wood chips are treated with chemicals, heat, and mechanical action to separate the cellulose fibers from other components like lignin and hemicellulose. The resulting pulp is then washed and bleached to remove impurities and achieve a high-purity cellulose material.

Once the cellulose pulp is obtained, it undergoes an alkali treatment to remove residual lignin and hemicellulose. In this step, the pulp is mixed with a hot alkali solution, usually sodium hydroxide (NaOH), and heated under controlled conditions. The alkali breaks down the lignin and hemicellulose, solubilizing them in the solution, while the cellulose remains intact.

The next step in the manufacturing process is the chemical modification of cellulose through etherification. Etherification involves introducing ether groups into the cellulose structure to enhance its solubility and other desired properties. Various types of ether groups can be introduced, such as methyl, ethyl, hydroxyethyl, hydroxypropyl, and carboxymethyl.

In this step, the alkali-treated cellulose pulp is converted into alkali cellulose by reacting it with an alkali metal hydroxide, usually sodium hydroxide (NaOH). The cellulose pulp is mixed with a solution of NaOH and heated, resulting in the dissolution of cellulose and the formation of alkali cellulose.

The alkali cellulose is then reacted with an appropriate etherifying agent to introduce the desired ether groups. The most commonly used etherifying agents are alkyl halides (e.g., methyl chloride, ethyl chloride) for alkyl ethers and alkylene oxides (e.g., ethylene oxide, propylene oxide) for hydroxyalkyl ethers. The reaction is typically carried out in the presence of a catalyst, such as tertiary amines or alkali metal hydroxides.

After the etherification reaction, the reaction mixture is neutralized to deactivate the catalyst and adjust the pH. This is usually done by adding an acid, such as hydrochloric acid (HCl). The neutralized mixture is then washed with water to remove any unreacted reagents, by-products, and impurities.

The purified cellulose ether is obtained by further processing the etherified product. Purification steps may include filtration, centrifugation, evaporation, and drying. These processes remove residual impurities, solvents, and excess reactants, resulting in a high-purity cellulose ether product.

Throughout the manufacturing process, quality control measures are implemented to ensure the desired properties and performance of the cellulose ether. Parameters such as viscosity, degree of substitution, moisture content, and purity are carefully monitored using analytical techniques.

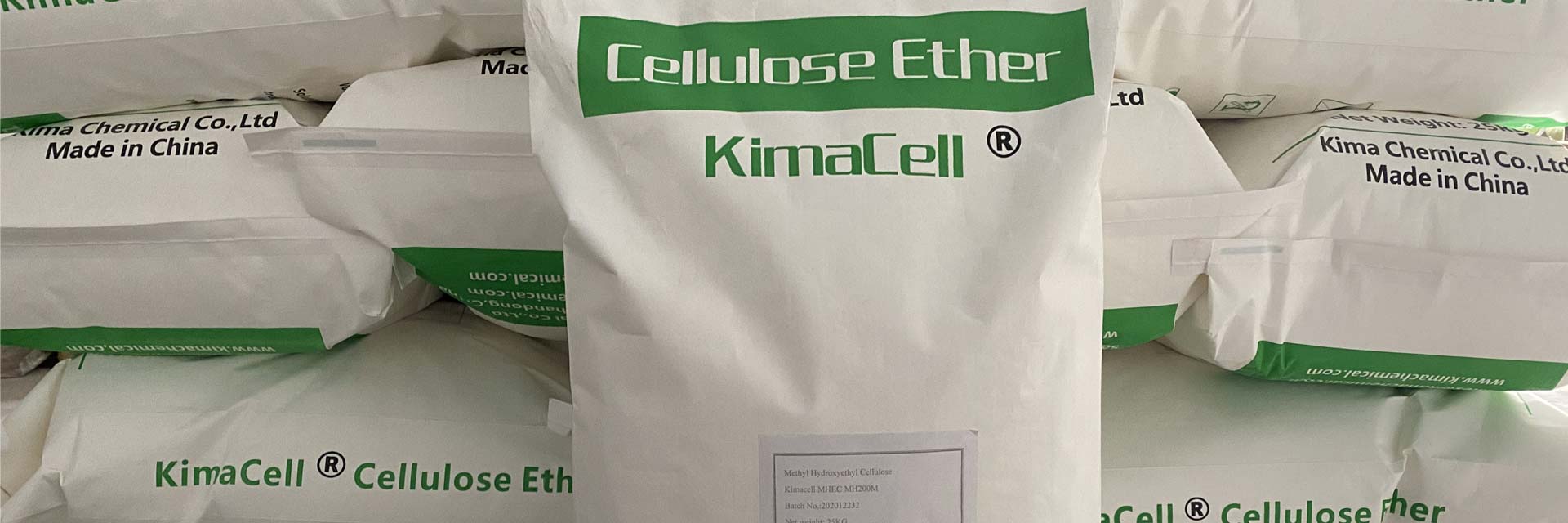

The final step in the cellulose ether manufacturing process involves packaging the product in suitable containers, such as drums or bags, and storing it in a controlled environment to maintain its quality and stability. Proper labeling and documentation are essential for traceability and regulatory compliance.

In conclusion, the manufacturing process of cellulose ethers involves the extraction of cellulose from natural sources, alkali treatment, etherification, purification, and quality control. Each step is crucial in producing cellulose ethers with the desired properties for various applications. The process requires careful control of reaction conditions, choice of etherifying agents, and purification techniques to achieve consistent and high-quality cellulose ether products.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland